- +60 16-688 4222

- info@flooringspecialistmalaysia.com

- Kuala Lumpur, Malaysia

flooringspecialistmalaysia.com

Menu

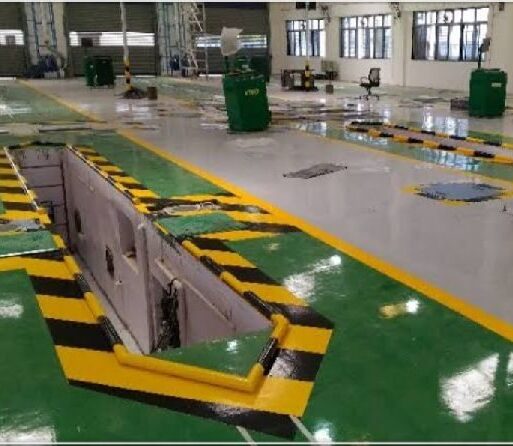

Industrial Epoxy Flooring

Epoxy comprise of a combination of resins and hardeners. When mixed together, the resin and hardener chemically react to form a rigid plastic material. The final material is strong, durable, resistant, and bonds extremely well to most base layers.

Epoxy floors are so strong that we usually install it in heavy traffic areas such as industrial environments, hospitals, or sports facilities. Hence, this is where industrial epoxy flooring is most known for.

Firstly, an epoxy coating will need a slightly porous and cleaned surface to adhere properly. Secondly, it is important to patch and repair all major cracks and chips before applying the epoxy. Thirdly, we do not apply epoxy coating over smooth concrete and the surface must be old enough to ensure a better adherence. Last but not least, be sure to remove all grease before applying the coating.

In addition, every manufacturing operation presents unique challenges that call for precise flooring solutions. Besides adding visual interest to industrial facilities, warehouses, or factories, industrial epoxy and other high performance resinous floor coatings can help improve workers’ productivity, as well as support their health and safety.

- Specialty epoxy and other resin-based polymers, can act as protectants on concrete floors. We usually install these floors on vehicle maintenance and air hangar floors.

- For food and pharmaceutical plants, flooring that inhibit bacterial growth and comply with the stringent sanitary requirements of each facility:

- 100% solids epoxy coating – These types of epoxy floor coatings apply seamlessand high build applications. Perfect for industrial floors, restaurants, kitchens, schools, hospitals, garage floors, and warehouses.

- Epoxy & polyurethane –Epoxy and polyurethane industrial floor coatings are easy to maintain. It is available in a variety of colors. Hence, it allows you to match your floors new look to the rest of the environment. Coatings are ideal for assembly and food processing areas, aircraft hangers, laboratories, clean rooms, pedestrian walkways, warehouses and similar industrial areas.

- ESD control epoxy flooring–In electronic components or volatile chemicals industries, static electricity can result in significant damage, injury and financial loss. ESD Coatings typically produce BVG of as low as 15 volts and are unaffected by relative humidity. We typically use these in computer store houses, and factories.

Standards Requirement in Industrial Flooring

Besides that, when talking about industrial epoxy system, we usually need to meet these standards in this industry.

- HACCP is a management system which apply food safety through the analysis and control of biological, chemical, and physical hazards. It covers from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product

- Good Manufacturing Practice (GMP)is a system for ensuring that we produce and control the products according to quality standards. It is to minimize the risks in any pharmaceutical production that cannot be eliminated through testing the final product.

Do read up on the benefits of epoxy as well as car park epoxy flooring. Call the Epoxy Flooring Specialist to help with your flooring that meets the required standards. Get it right the first time.